Understanding Gearbox Syncro Mechanisms

What is a Gearbox Syncro?

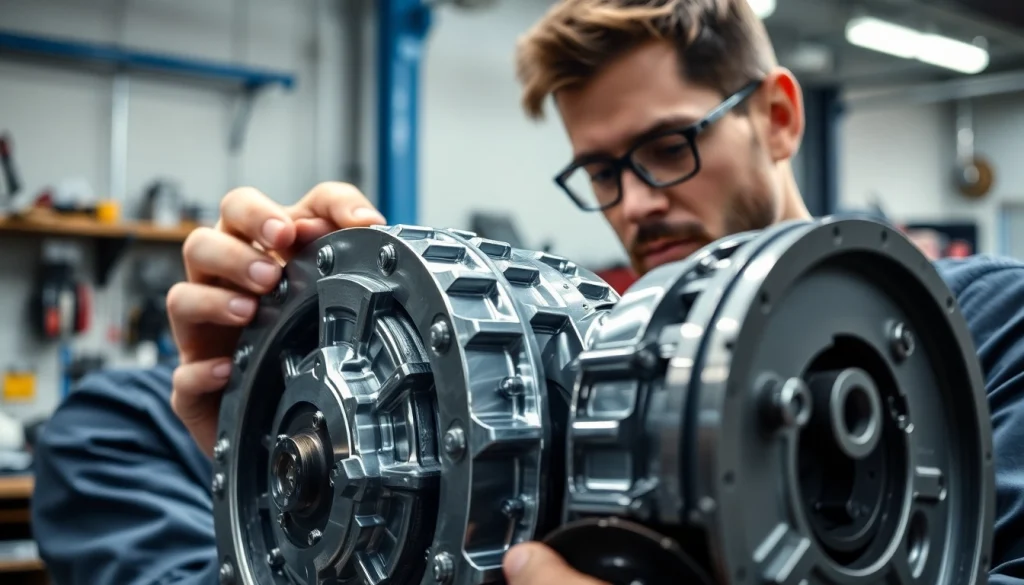

In the world of automotive engineering, the gearbox syncro is an essential component that plays a crucial role in the shifting process of a vehicle’s transmission system. Essentially, a gearbox syncro, or synchronizer, is a device within the gearbox that ensures smooth and efficient gear shifting. It does this by matching the speed of the gear being shifted to the speed of the output shaft, allowing for seamless engagement between gears without any grinding or jarring. This mechanism is vital for manual transmissions and contributes significantly to the overall driving experience.

How Gearbox Syncros Function

The operational principle of a gearbox syncro is based on the concept of synchronization of speeds between the gear and the shaft onto which it is being engaged. When the driver shifts gears, a sleeve moves towards the desired gear. This sleeve comes into contact with the synchronizer ring, which attempts to match the speed of the gear to the speed of the shaft. As the ring slides under the surface of the gear, it effectively brakes the gear until both parts reach the same rotational speed. Once this synchronization is achieved, the gear can be actively engaged, allowing for smooth transitions during gear shifts.

Benefits of Enhanced Gearbox Syncros

Enhanced gearbox syncros provide numerous benefits, enabling vehicles to perform better on the road. First and foremost, they improve gear shifting smoothness, which translates into a more comfortable driving experience. Additionally, better syncros minimize wear on transmission components, thus extending the lifespan of both the gearbox and the clutch. Furthermore, advancements in syncro technology can lead to faster gear changes, enabling sports cars and high-performance vehicles to maximize their output during critical driving situations. Lastly, enhanced syncros may help in reducing the chances of damage caused by improper gear engagement, thereby enhancing overall vehicle reliability.

Common Issues with Gearbox Syncros

Identifying Gearbox Syncro Problems

Recognizing issues related to gearbox syncros is fundamental for maintaining vehicle performance. Some common indicators include difficulty in shifting gears, grinding noises when changing gears, or experiencing a feeling of slippage. These signs often point to failing syncros, which can affect the entire transmission system if not addressed promptly. Mechanics often use diagnostic tools to identify any points of failure within the syncro mechanism, checking for wear, misalignment, or defective components that might need replacement.

Symptoms of Wear and Tear

As gearbox syncros undergo wear and tear over time, there are several symptoms that may emerge. Drivers might notice an increase in the force required to shift gears, abnormal sounds like grinding or clunking during engagements, or a sensation of the gear slipping unexpectedly. These symptoms should not be ignored as they may signal underlying problems that, if not corrected, could lead to larger transmission failures and significant repair costs. Regular inspections and attention to these signs can help in catching syncro-related issues early, before they escalate into more extensive vehicle damage.

When to Seek Professional Help

If you encounter any of the aforementioned symptoms, it is essential to seek professional help. A qualified mechanic can conduct a thorough inspection and perform necessary repairs or replacements. Generally, it’s advisable to address syncro issues as soon as they arise, as delaying repairs can lead to additional complications, prolonged repair times, and increased costs. If gear shifting becomes impossible or erratic, immediate assistance is warranted, as this could indicate a severe problem that risks further damage to the gearbox.

Best Practices for Maintaining Gearbox Syncros

Regular Inspection Techniques

Regular inspections are vital for the health of gearbox syncros. It is recommended to conduct these inspections at least once a year or before significant journeys. Mechanics will check for fluid leaks, listen for unusual sounds while shifting, and ensure that linkage adjustments are properly calibrated. During these inspections, it is also critical to check the condition of transmission fluids. Deteriorated fluids can lead to performance issues in syncros due to inadequate lubrication, therefore regular fluid changes should be a part of maintenance routines.

Lubrication and Cleaning Tips

Proper lubrication of syncros is essential for high performance. Using high-quality, manufacturer-recommended transmission fluids will ensure that the syncros can function optimally. Similarly, keeping the gearbox clean enhances the efficiency of the syncros and prevents debris from causing unwanted wear. It’s advisable to clean the gearbox of any contaminants during fluid changes, utilizing materials like compressed air to blow out dust and particles that may have accumulated. Routine maintenance and cleanliness will significantly extend the lifespan of gearbox syncros and the overall transmission system.

Quality Replacement Parts

When it comes to replacing worn or damaged syncros, opting for quality parts is paramount. While there are many aftermarket options available, genuine manufacturer parts are often the best choice, as they match the vehicle’s specifications perfectly. Although they may be more expensive, they provide better performance, assurance of quality, and further durability. Consult with automotive specialists to select the proper syncros that will ensure reliability and effectiveness in your gearbox.

Choosing the Right Gearbox Syncro for Your Needs

Types of Gearbox Syncros Available

There are various types of gearbox syncros available, each designed for specific transmission systems and vehicle models. Common types include cone syncros, which use a cone-shaped surface contact for engagement; multi-cone syncros, which offer multiple engagement points for better durability; and dog-eared syncros, often used in racing applications to allow quick gear changes. Understanding the type of syncro that is best suited for your vehicle can greatly impact performance and handling. Research vehicle specifications and consult professionals to make informed choices.

Factors to Consider in Selection

When selecting a gearbox syncro, consider factors such as the type of vehicle, driving conditions, and desired performance outcomes. For example, off-road vehicles may benefit from sturdier syncros that can withstand rough terrain, while high-performance cars may prioritize rapid gear shifting and responsiveness. Additionally, the compatibility of syncros with existing parts is crucial; mismatched components can lead to further mechanical issues and inefficiencies. Always consult with automotive specialists to weigh your options effectively.

Cost vs. Quality Analysis

Balancing cost and quality is a vital aspect of selecting gearbox syncros. While cheaper options are available, they may not provide the same performance or reliability as premium products. Investing in higher-quality syncros can save long-term costs by reducing wear on your transmission and maintaining optimum performance. A thorough market analysis, alongside consultations with automotive professionals, can help achieve a balance between budget constraints and the need for quality parts, ensuring superior performance and longevity for your vehicle’s gearbox.

Future Trends in Gearbox Syncro Technology

Innovations in Gearbox Engineering

The field of gearbox engineering is evolving rapidly, with innovative technologies advancing the function and design of syncros. Recent trends include the development of lighter and stronger materials such as carbon composites that enhance strength while reducing weight. Additionally, the integration of advanced manufacturing techniques such as 3D printing is producing syncros that provide superior precision and reliability. As technology progresses, we can expect further improvements in gear engagement methods and the overall efficiency of gearbox systems.

Smart Technologies Impacting Gearbox Syncros

Smart technologies are beginning to influence how gearbox syncros are designed and utilized. Systems equipped with sensors can provide real-time feedback on syncro performance and wear levels, allowing for predictive maintenance. With the rise of electric and hybrid vehicles, new syncro designs are being adapted for unique powertrains, increasing the versatility of gearbox systems. The integration of artificial intelligence will further impact the tuning and calibration of syncro systems, optimizing performance under varying conditions.

How to Stay Informed about Developments

Keeping abreast of developments in gearbox syncro technology is essential for enthusiasts and professionals alike. Subscribing to automotive engineering journals, attending industry conferences, and engaging with professional networks are great strategies to stay informed. Many manufacturers also provide updates on technological advancements through newsletters or online platforms. Additionally, following key industry figures and experts on social media can offer insights into emerging trends and innovations in gearbox technology.